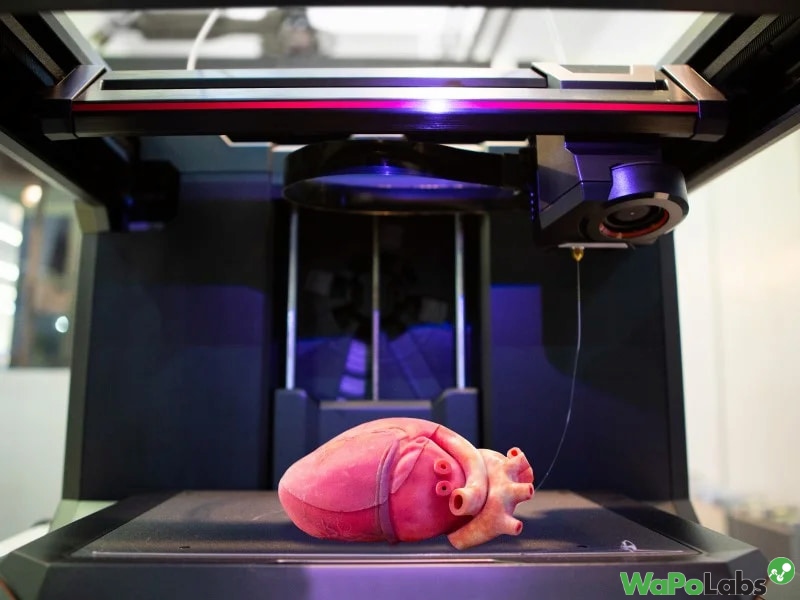

The groundbreaking technology of 3D printing will ultimately lead to quicker, more efficient, and more individualized medical treatment. This straightforward method allows for the quick, low-cost, and high-throughput fabrication of geometrically well-defined 3D printed organs. The risk of rejection is decreased and the need for organ donors may be eliminated by bioprinting organs and tissue patches from a patient’s own cells. Find out more about 3d printing organs techniques in this article!

What are 3D Printed Organs?

A 3D-printed organ is an artificial device designed to replace an internal organ, manufactured using 3D printing. The primary purpose of printable organs is transplantation. Research is currently underway on artificial heart, kidney, and liver structures, as well as other vital organs.

For more complex organs, such as the heart, smaller structures such as heart valves are also subject to study. Several 3D print organs are approaching functional requirements for clinical performance, and are mainly composed of hollow structures such as the bladder, as well as vascular structures, and urinary tubes.

3D printed organs method allows layer-by-layer construction of a specific organ structure to form a cell support structure. This can be followed by cell propagation, in which cells of interest are injected directly into the supporting structure. In addition, the process of integrating cells into the printable material itself, rather than performing subsequent seeding, has been explored.

Modified inkjet printers were used to produce three-dimensional biological tissue. The printer cartridges are filled with a suspension of living cells and a smart gel, the latter of which is used to provide structure. Alternating patterns of smart gels and live cells are printed using standard printing nozzles, with the cells eventually coming together to form tissue. When finished, the gel is cooled and washed away, leaving only living cells.

The ultimate objective of organ printing is to create organs that can completely integrate into the human body. Successful organ printing might have an influence on a number of sectors. These include the training of doctors and surgeons, pharmacological research, and artificial organ transplants.

History of 3D Organ Printing

3D printing to produce a cellular structure was first introduced in 2003, when Thomas Boland of Clemson University patented the use of inkjet printing for cells. This process uses a transform point system for the deposition of cells into organized 3D matrices placed on a substrate.

From Boland’s initial findings, 3D printing of biological structures, also known as bioprinting, has been further developed to include the production of tissues and internal organ structures, as opposed to cell matrices. In addition, more printing techniques, such as bio-extrusion, were studied and subsequently introduced as a means of production.

Organ printing has been approached as a potential solution to the shortage of donated organs. Organs have been successfully printed and performed in clinical settings that are flat, such as skin, vascular tissue, such as blood vessels, or hollow organs, such as the bladder. When artificial organs are prepared for transplantation, they are usually manufactured with the recipient’s own cells.

More complex organs, namely those with solid cellular structures, are being studied; These organs include the heart, pancreas, and kidneys. Estimating when such an organ is printable, a variety of treatments may be possible. In 2013, the company Organovo manufactured a human liver using 3D bioprinting, although it is not suitable for transplantation, and is mainly used as a vehicle for drug testing.

3D Organ Printing Techniques

A significant area of research in biological engineering has been the use of 3D printing to create artificial organs. There are numerous methods for conducting 3D-printed organ production, each of which offers unique benefits that may be appropriate for particular types of organ production.

SWIFT

A technique for printing organs called “sacrificial writing into function tissue” (SWIFT) uses live cells that are firmly packed to resemble the density seen in the human body. When packing, tunnels that resemble blood veins are cut, and via these tunnels, oxygen and vital nutrients are given.

This approach combines previous procedures that merely packed cells or produced vasculature. With its combination of both, SWIFT advances research toward the development of useful artificial organs.

Fused deposition modeling

Comparatively speaking, fused deposition modeling (FDM) and selective laser sintering are more popular and less costly. This printer employs a printhead that resembles an inkjet printer, but it does not require ink. The printhead moves while releasing heated plastic beads, which are used to build the object in thin layers.

The hot plastic binds or fuses with the layers below as it is deposited from the printer. As additional layers are added to the construction, they stiffen as they cool and eventually take on the solid shape that was meant to be formed.

Stereolithographic (SLA)

This technique of printing organs layers a 2D pattern through selective photopolymerization in the bio-ink reservoir using spatially controlled light or laser. The 2D pattern may then be used to construct a 3D structure in layers.

The bio-ink is then taken out of the finished item. SLA bioprinting enables the production of intricate interior structures. The sole drawback of this technology is the dearth of biocompatible resins, despite the extraordinarily high feature resolution.

Selective laser sintering

Powdered material serves as the printing substrate in the selective laser sintering (SLS) process. Objects made of metal, plastic, and ceramic may be produced with SLS. In this process, the powdered material is sintered using a laser that is powered by a computer. The desired object’s shape is etched into the powder by the laser, which then fuses the powder into a solid.

The procedure is then repeated, constructing each layer one by one as each fresh layer of powder is applied until the complete thing has been created. SLS-based 3D builds of craniofacial implants and scaffolds for heart tissue engineering are recent developments in organ printing.

Extrusion bioprinting

Extrusion bioprinting is the constant application of a particular printing material and cell line from an extruder, a mobile print head of sorts. This usually results in a more delicate and regulated handling of the fabric or cell assertion and enables the use of higher cell densities in the creation of 3D printed organs.

In any event, the slower printing rates caused by this process negate these advantages. UV light is commonly used in conjunction with extrusion bioprinting to photopolymerize the printed cloth and produce a more stable, coordinated build.

How are Bio 3D Printing Organs Different From Conventional 3D Printing Organs?

In fact, 3D printing technology has been in development since the 1980s. Its original purpose was to find an efficient and optimal way to create solid objects, such as machine parts. industrial service. 3D printing will replace traditional manufacturing methods such as cutting, molding, or extrusion.

Patents for the first 3D printing techniques were protected for 20 years. As soon as it expired, the application in the field of 3D printing exploded. Now, you can find a 3D printer anywhere, and it will print everything from toys, and machines to a whole house.

However, 3D printing will become a completely new technique, if it becomes bio 3D printing to work with cells.

For example, bio 3D printing requires to be performed under aseptic conditions to avoid contamination of the printed sample. The environment must also have the right temperature and humidity so that the cells do not die. In addition, the materials used in biological 3D printing cannot be the materials in conventional 3D printing, because most of them require high temperatures or solvents that are toxic to life.

Currently, scientists are still looking for materials that could be used for a bio-3D printer. The challenge here is that we will need many, not just a single material.

For example, bones will need a strong and durable material. The heart muscle needs elasticity and soft organs like the liver need a flexible and compressible material.

In a new study published in the journal Advanced Healthcare Materials, scientists discovered a new material extracted from seaweed. It can be used to bio-3D print stem cells without harming their survival. The authors believe that this new finding will pave the way for the printing of complex tissue structures in the future.

Applications of 3D Printed Organs in the Near Future

It will take us many years and billions of dollars to print out all the parts of the human body. But it is not always necessary to go to the destination for the new 3D printed organs to be applied.

Currently, the end-to-end cost to bring a drug from research to market is about $2.5 billion. The process takes an average of 10 years, and each drug has less than a 10% chance of being approved.

When a drug reaches the stage of human testing, its success rate is only 10-15%. Meanwhile, patients participating in the trial will face a high risk, even death.

We know that drug trials fail because drugs work well in animals but poorly in real patients. The species gap between test subjects, from mice to primates and humans, is huge. Therefore, we must find a way to draw them closer.

While creating organs in animals, using gene-editing techniques is new, bio 3D printing can also help. Several pharmaceutical companies have begun working on the idea of printing out models of the liver, kidney, or heart for drug testing.

Therefore, for many industries, product researchers and developers will also have to find new directions with currently available technologies. Which in the near future, most likely will be bio 3D printing.

Above is all the information associated with 3D printed organs. Hope this article can give you beneficial information in case you want to try this modern and effective therapy method. Good luck!

Wapolabs USA

- Address: 1301 K Street NW Washington, D.C., U.S. 20071

- Phone: 0190-8286

- Email: [email protected]

- Website: https://www.wapolabs.com

- Instagram: https://www.instagram.com/wapolabs/